Some support activities were actually part of the regimental organization. A prime example was the regimental Motor Pool. An engineering regiment’s standard equipment included twenty D8 Caterpillar bulldozers, ten D4 Caterpillar bulldozers, three half cubic-yard shovels, six LaTourneau 12-yard carry alls, six Adams leaning wheel graders, six Rooters, three Galion road graders and six additional caterpillar leaning wheel graders. They also received sawmills and pile drivers.

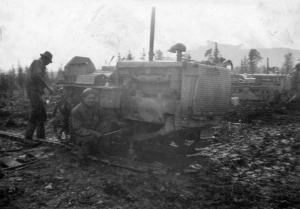

A regiment building road, operated its equipment 24-7 through mud, permafrost, muskeg, rain and dust. Spare parts were hard to come by. Often the motor pool cannibalized parts from deadlined equipment – especially coveted dozer tracks.

Massive fuel dumps kept equipment moving but the Motor Pool struggled to perform maintenance. Oil thickened and froze in the cold. Mud sucked hydraulic hoses loose from their fittings draining precious fluid. In summer dust and grit mixed with lubricants transforming them into liquid sandpaper.

Each line company had a platoon of mechanics to perform routine maintenance and make on the spot repairs. The Motor Pool supplied parts and performed less routine repairs and maintenance.

Interviewed in 2014, Lt. Mortimer Squires who served early on as Motor Officer for the 93rd remembered SSgt. Alexander Jefferson. Jefferson could fix anything. In convoy he always travelled at the rear so he could repair any breakdowns.